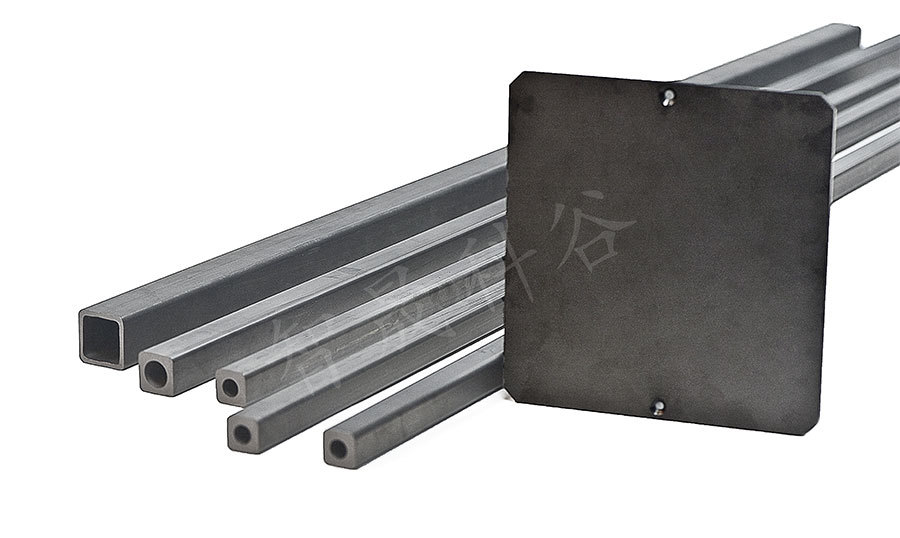

Silicon carbide rollers

The pressureless sintered silicon carbide rollers has the largest bearing capacity and the best oxidation resistance

keywords:

classification :

Silicon carbide roller

Tel:

Email :

Silicon carbide rollers

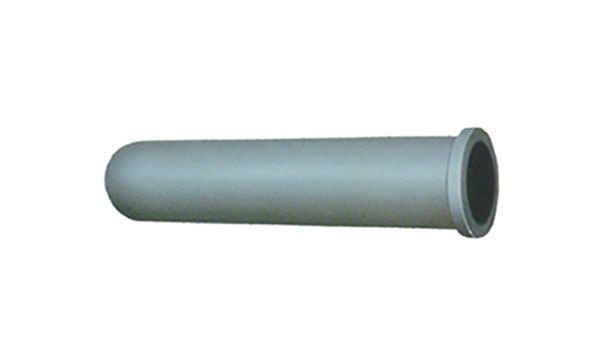

The pressureless sintered silicon carbide rollers has the largest bearing capacity and the best oxidation resistance.It can be used below 1650℃in oxidation atmosphere and has comprehensive corrosion resistance,which can be applied in any high temperature corrosion and harsh working conditions.

With the development of power battery,lithium cobalt oxide(LCO),ternary materials Nickel cobait lithium manganate(NCM),lithium manganese oxide(LMO)and lithium iron phosphate(LFP),which are the positive materials for commercial production of lithium battery,need high-temperature sintering in the preparation process.During high-temperature sintering,strong alkaline corrosive gas will be volatilized,reaction bonded silicon carbide rod contains 10-16wt%Si,which will react with the volatile corrosive gas at high temperature.The service life of the stick is greatly reduced and the maintenance cost of the kiln is increased.

The pressureless sintered silicon carbide rollers does not contain metal Si,and the bulk density can reach more than 97%of the theoretical density.The service life under the same working condition is 5 times that of the reaction sintered silicon carbide,and is nearly 10 times of the life of silicon nitride bonded silicon carbide.It is nearly 15 times the service life of recrystallized sintered silicon carbide.